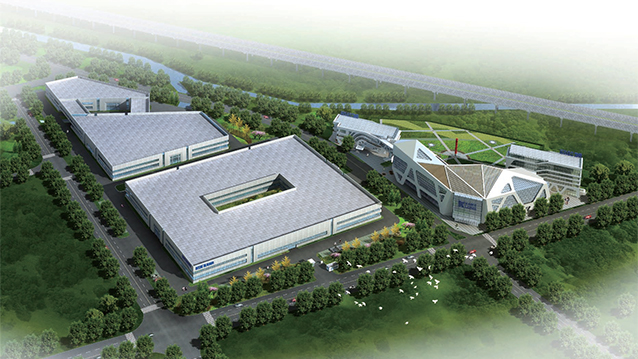

Kailong High-tech, pioneering technology innovation to make the sky bluer, advances with a dedication to green environmental protection and leadership in the industry

Leading the way in national carbon summits and carbon neutrality strategy goals, our company embarks on a mission to produce environmentally sensitive solutions. We have joined forces with leading names in the industry through strategic partnerships

By collaborating with prestigious companies such as Weichai, Yuchai, Xichai, Sdec, Faw Jiefang, Saic Hongyan, Naveco, Quanchai, Yituo, Lovol, Changchai, we strengthen our leadership in the industry. Kailong High-tech develops and manufactures advanced technology products in various fields such as commercial vehicle exhaust aftertreatment systems and intelligent environmental protection products that meet national VI emission standards.

Our products, including water and electricity used in a wide range of applications from automobiles to ships, from agricultural machinery to engineering machinery, such as methanol, fuel heaters, ice melters, and centralized lubricators, play a critical role in the process of controlling exhaust and industrial pollution of power devices.

As Kailong High-tech Co., Ltd., we are committed to supporting environmental sustainability and reducing industrial pollution through technological innovation. By contributing to the future of our customers and society, we not only enhance our business but also fulfill our mission to make our world a more livable place.

Among the regions where we represent Kailong High-tech Co., Ltd. as Tekhne Marine, there are strategic markets such as Africa, the Middle East, Russia, and Turkey. By strengthening our presence in these regions, we continue our efforts to provide our customers with more comprehensive services and to promote our environmentally friendly technologies.

DOC+DPF

DOC+DPF system includes DOC components, DPF components, mixer components, SCR components, and heat insulation components. It features a compact structure, pleasing appearance, high conversion efficiency, low back pressure, easy maintenance, and low operating cost. It removes CH compounds and particulate matter. It is widely used in the exhaust aftertreatment system of off-road CN IV low-powered mobile machinery.

Marine SCR Control System

It can visualize the basic parameters of the system with functions such as touch screen, alarm, emergency brake stop, manual control, etc. The control system is an integrated module consisting of collection, control, display, and alarm. It is commonly used in conjunction with the SCR system in ship engines, generator sets, and machinery reconstructions.